Clothing and Footwear Market for Businesses: How the Small Quantity Wholesale Clothing Model Works

July 10, 2025

Microbrands, showrooms, Instagram shops, and local fashion spots have become a solid part of the market. Their growing presence drives demand for small wholesale batches of clothing and footwear. This strategy lets businesses make quick purchases, test products with their audience, and reorder when items perform well.

For suppliers, this shift presents both challenges and opportunities. Is working with low-volume batches profitable? How can production adapt to these requirements? And which sales models are best suited for niche fashion brand sourcing today? We’ll explore these questions in the article.

Micro and Small Businesses: A Growing Market Segment

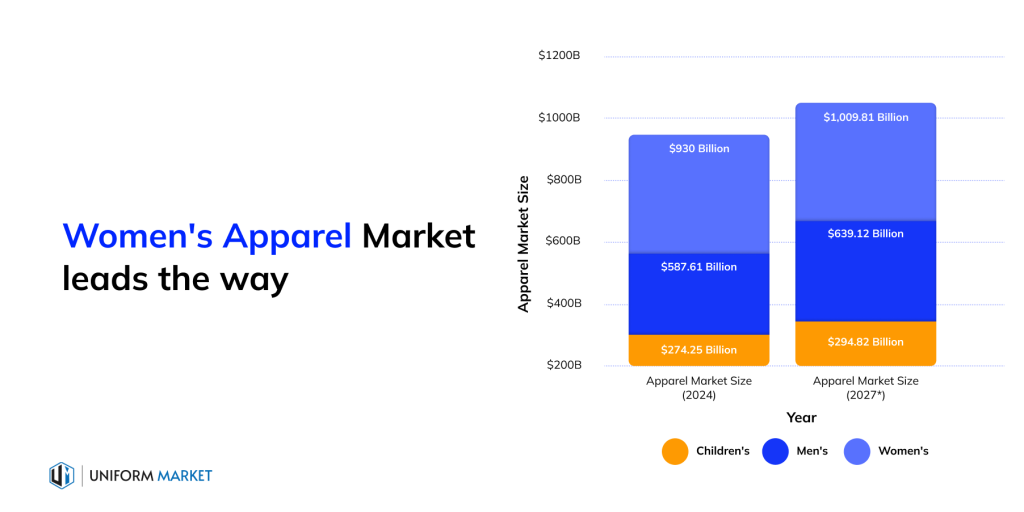

The global apparel market is on a steady upward trend. According to UNIFORM MARKET, its value is projected to reach $1.84 trillion by 2025, representing 1.63% of global GDP.

Women’s apparel holds the largest share, currently valued at $930 billion and expected to exceed $1 trillion by 2027. In comparison, the men’s segment is valued at $587.61 billion, while children’s wear accounts for $274.25 billion.

At the same time, consumption patterns are shifting. More fashion companies are moving away from mass production and focusing on narrow niches — eco-material women’s lingerie, local streetwear shoes, garments for nursing mothers, or unisex collections with a ’90s aesthetic.

These brands often operate under the direct-to-consumer (DTC) model, allowing them to test demand without heavy inventory costs and stay highly flexible. Their priorities include:

- React quickly to shifting trends

- Minimize costs when launching new products

- Order in limited quantities to reduce budget and inventory risks

That’s why buyer expectations for apparel microbusiness wholesale is rising fast — a format where what matters most isn’t volume, but speed, service, and the ability to handle compact orders.

One of the biggest challenges for these companies is the high MOQ (minimum order quantity). Many manufacturers only work with lots starting at 200–300 units. But for a small label, that’s a major investment — hard to justify without steady demand. That’s why they look for providers willing to work with 20–50 units or even fewer.

These brands typically search for:

- Low MOQ clothing supplier

- Small batch footwear manufacturer

- Dropshipping fashion suppliers in Europe

The new generation of clients is mobile, experimental, digital, and often already has an audience on Instagram or TikTok. They’re not afraid to launch new lines every month, quickly drop slow-selling items, and need a supplier who can keep up with their pace.

For manufacturers, this opens the door to a steady, fast-moving consumption flow. Those who can meet the needs of this segment will gain a clear competitive edge — both now and in the years ahead.

How Manufacturing Adapts to Small Batches

The traditional “bigger is cheaper” practice is no longer universal. Instead, the focus shifts tosmall batch clothing manufacturing, which relies on:

- Shorter production cycles

- A flexible apparel supply chain

- Quick access to raw materials or fashion stock reserve sales

Demand for custom clothing small runs is on the rise, transforming how businesses approach purchasing. More companies are shifting from mass orders to limited, personalized batches that respond quickly to changes in consumer needs. According to the Custom Clothing Market Report 2025 (Global Edition), the market was valued at approximately $50 million in 2024, with a projected annual growth rate of 9.8% through 2033.

The custom wearables short-run category includes:

- Capsule collections updated several times per season

- Test series before scaling a product

- Limited drops that keep the regular audience engaged

This approach gives ventures flexibility but also brings new challenges:

- Higher unit costs compared to mass manufacturing

- More complex planning, requiring management of varying volumes and tight deadlines

- Increased communication between brand and manufacturer to handle design changes, timelines, and shifting priorities

However, this approach plays a key role in the evolving approach to purchasing. Its value becomes even more apparent when paired with the clothing pre-order business model, where fulfillment starts only after receiving confirmed orders. This method helps prevent overproduction and unsold stock while allowing for more accurate demand planning.

When Small Batches Pay Off

The idea that minimal production runs lead to lower profits is becoming less relevant. In reality, a flexible small-quantity supply model can be just as profitable as traditional wholesale — and in some cases, even more so.

This approach offers several key financial advantages.

- Higher margins come from customization and service. Emerging businesses are ready to pay more for flexibility — whether it’s the ability to order limited quantities, customize materials or details, or get quick feedback and updates. In this market, service quality and speed often matter more than bulk discounts. That allows distributors to charge higher margins and balance lower volumes with better profit per unit.

- Faster cash flow and reduced risks. With limited lots, capital isn’t locked into unsold inventory. Products move faster, and the risk of overstock drops. This framework supports quicker product updates and more agile decision-making. Suppliers get paid sooner and can restart creation cycles without long delays.

- Regular repeat orders = steady income. Focused brands typically place frequent, low-volume orders, giving manufacturers a consistent fabrication flow rather than sporadic bulk requests. Dropshipping enhances this by allowing manufacturers to hold inventory themselves, cutting storage costs for clients. According to Fundera, suppliers using dropshipping earn an average of 18.3% more profit than those selling through traditional warehouse or distribution channels.

Here’s a look at the business models that work best with small batches:

| Model | How it Works | Advantages |

| Pre-order | Production starts only after confirmed orders are received. | Minimal risk, accurate planning |

| Dropshipping | A supplier ships orders directly to the end customer. | Low costs for clients, higher supplier margins |

| Stock reserve | Maintains a minimal inventory of popular items for quick fulfillment. | Flexible, fast delivery, steady turnover |

These strategies fit perfectly within today’s small quantity wholesale clothing and wholesale shoes low MOQ approach, where flexibility, quick response, and minimizing excess costs are essential.

Tips for Suppliers Looking to Scale Through Small Batches

To tap into the growing demand for low-volume orders, producers need to adjust their strategies, both in production and client relations. Here are five practical steps to get started:

- Rethink your MOQ. If your current minimum order is 300 units, try offering 50–100 units. Even a slight drop in MOQ can open your business to a wider range of clients — from niche labels to showrooms and startups.

- Offer basic customization. Let customers choose fabrics, hardware, colors, or add logos. Even limited options allow entrepreneurs to create distinctive products and justify paying more for flexibility.

- Work with pre-orders. Producing on demand helps plan workloads more accurately and reduces the risk of leftover stock. This is especially beneficial for products with seasonal or short-term sales cycles.

- Segment your offerings for different client types. Set different conditions for large and small orders — for example, a basic line starting at 50 units and custom collections at 200. This strategy attracts more clients without hurting profits.

- Optimize internal processes. To handle minimal batches efficiently, review workflows and admin processes: automate routine tasks, stock popular materials, and schedule production changes flexibly. This will cut lead times and reduce costs.

The market is evolving, and these changes are here to stay. Micro fashion businesses in Europe are emerging as a powerful segment, triggering preference not for mass deliveries but for flexible, frequent, and small-volume orders.

Suppliers who adapt quickly will gain the advantage. By providing quality, customization, and fast turnaround, small batches won’t be a constraint — they’ll become a reliable source of profit. Your company can become a trusted partner for this new wave of fashion.

If you want to explore new business models without extra costs and quickly connect with both business clients and end consumers, online platforms are a great place to start. They help cut launch expenses, simplify logistics, and provide ready-to-use promotion tools. Try listing your products on [ServiCom] to see the potential of the small batch approach in action.